Understanding Oil 103

The Stribeck Curve

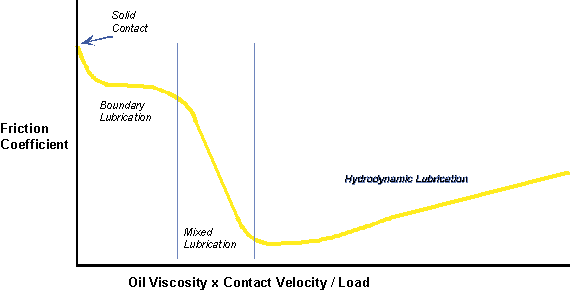

To understand the importance of correct viscosity choice and usage, the Stribeck curve is an excellent visual methods of showing how load, RPM and film strength effect the various lubrication layers of engine oil.

The Stribeck Curve is a plot of the friction as it relates to viscosity, speed and load. On the vertical axis is the friction coefficient. The horizontal axis shows a parameter that combines the other variables: mN/P. As you move to the right on the horizontal axis, the effects of increased speed, increased viscosity or reduced load are seen. The zero point on the horizontal axis corresponds to static friction

When you have a combination of low speed, low viscosity and high load this produces boundary layer lubrication. Boundary layer lubrication, as mentioned previously, is when there is too little fluid in the surface area and the surfaces make contact. As you can see with the Stribeck curve this results in very high friction. As the speed and or viscosity increases the load on the surface decreases and the surfaces begin to separate and create a fluid film. This results in mixed lubrication where a small film is in place but there might be areas where the surface still makes contact. At the point where hydrodynamic lubrication begins is where you see the lowest friction coefficient. By this time the load on the surface is completely supported by the fluid film.

Now, the interesting part of this chart is where you will notice the friction increasing within the hydrodynamic region. This is due to fluid drag (friction caused by the fluid). Higher speed can result in a thicker fluid film but it also increases the amount of drag on the moving surfaces. As an example think about how much harder it is to run in a pool of water than to simply walk.

Engines will see boundary layer lubrication during starts and shutdowns due to the thinner film and low speeds. During a startup the oil will quickly transition to a hydrodynamic lubrication range. The Stribeck curve shows that engines will see their highest amounts of wear during starts and shutdowns.

The Stribeck curve is a scientific example of why having proper viscosity choice is important not only in a street application but also with a race application. With street cars, having a viscosity that provides the right amount of film strength in high load, low speed situations is important due to the typical lower RPM operational conditions encountered on the street. However, if fuel mileage is a concern you do not want to have such a high viscosity that you have large amounts of fluid drag.

With racing applications you want to maintain as low of a friction coefficient as possible while maintaining the best protection. Since race motors are ran at higher RPMs they will be able to generate more film strength and thus have more protection even in high load situations. As such, using a higher viscosity oil with race motors is not always necessary. In race situations where every horsepower counts, having an oil which generates the most engine efficiency is critical. Correct viscosity could mean the difference between 3whp to 6whp!